Induction of the 500th engine and 400th service visit – we are celebrating more round anniversaries!

Recent weeks have brought us symbolic round numbers, and significant milestones in EME Aero’s operational growth. In mid-March we completed our 400th service visit, and last week we inducted our 500th engine for service! Take a quick recap and a brief overview of our operational achievements – from the start of operations to now.

From the first repairs to performance at the level of several hundred service visits

At the end of 2019, we started operations and inducted our first engine for service. Today, less than 4.5 years from that date, we are celebrating together the round symbolic acceptance of the 500th engine. What made up this number and what challenges did we face to reach it?

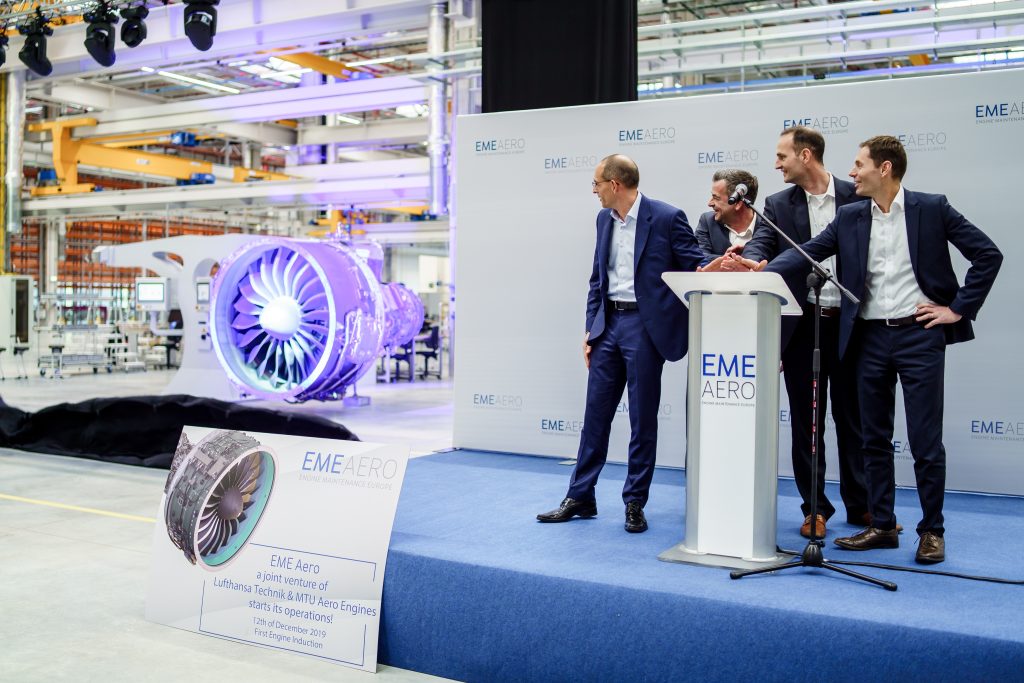

In December 2019, just 18 months after the start of the first construction work, we completed the certification process and moved from temporary premises to the newly built EME Aero plant.

Among the first employees and shareholders, we officially inaugurated the start of operations and celebrated the arrival of our first ever engine. During the ceremony, by symbolically pressing a red button and visualizing a clock on the screen, we launched the counter of our first TAT. Soon, in December, we will celebrate the 5th anniversary of this event!

For the first regular service visit finalized, we consider the PW1100 Medium engine, were we have to originally replace the combustion chamber. After a detailed incoming inspection, the workscope was expanded to other modules as well, recalls Grzegorz Niedźwiedź, Production Control Manager.

Team development and expansion of service capabilities

In our first year of operations, we took on 35 PW1100 engines at EME Aero. In 2021, we expanded our maintenance capabilities by introducing another engine type to the portfolio – the PW1500G. In the Autumn of 2023, we celebrated the completion of the first service visit for the PW1900G engine – the third engine type we service at EME Aero. We are growing technically, process-wise and structurally – we have a complete engine portfolio, and we already have nearly 1000 people on board!

Over the past few years, I see significant progress in developing the experience of our team, in all areas. On a daily basis, you can see the commitment of the entire staff and the high awareness of the product we work with. Our approach to work and continuous efforts to optimize processes, results in an increasing number of engines we receive and send to our customers. We have undoubtedly become a plant that plays a significant role in the MRO GTF family, Grzegorz concludes.

Focus on Heavy Engines – what made up the number of 500 inductions?

The scope of our maintenance has changed and expanded with successive certifications, the introduction of new service procedures as well as the broadening of staff qualifications. Currently servicing the three types of engines in the GTF family, we have the capacity to perform repairs ranging from quick, targeted visits to full, extensive overhauls resulting from engine operation and standard maintenance. We are one of two MRO facilities in the world performing service on the PW1900G engine.

By the range of repairs performed, it can be seen that we are a facility focusing on the most complex service of engines. As much as 71% of the engines that come to us are Heavy (71%) – that is, requiring the most difficult, complicated and time-consuming repairs and maintenance.

Statistics show that we have shipped engines to our customers on average every third day since we started. The number of projects we done brought us all a lot of challenges every day, but in my opinion, also a lot of satisfaction, Grzegorz concludes.

The 500th scheduled visit is one where the PW1500 engine will be processed in QuickTurn mode (i.e., limited repair, shorter than standard service time).

The 400th completed service visit and the induction of the 500th engine is something we could not have achieved without a close-knit, ambitious and experienced team. From my side, I would like to congratulate everyone on this achievement, concludes Robert Maślach, Managing Director of Operations, COO.